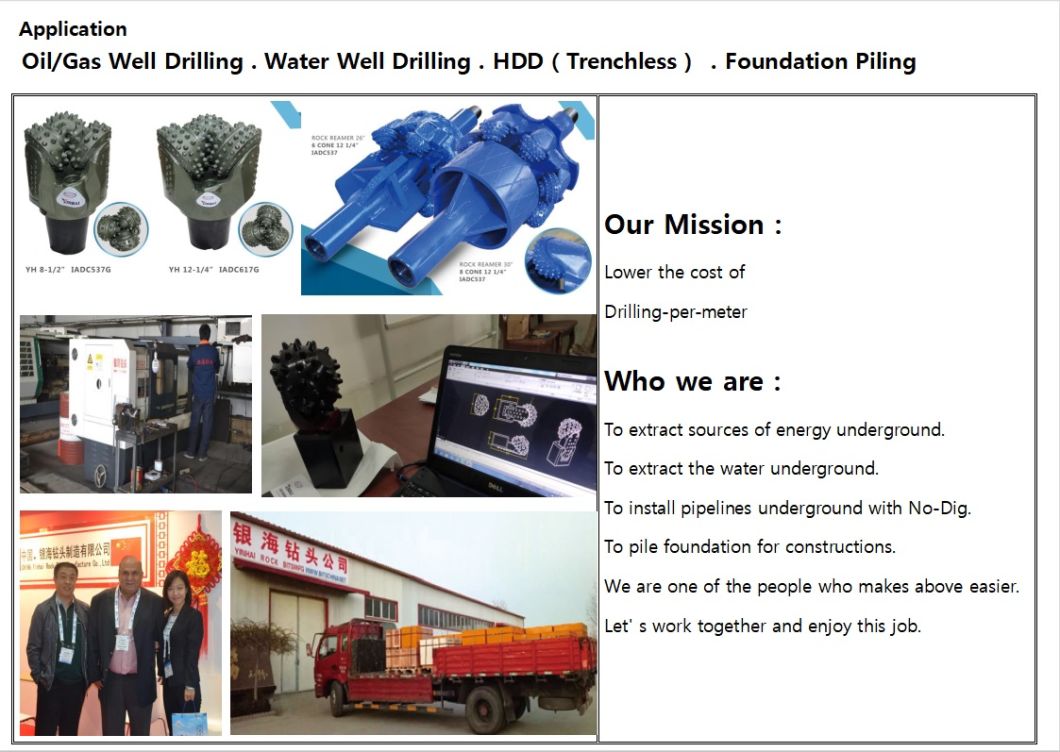

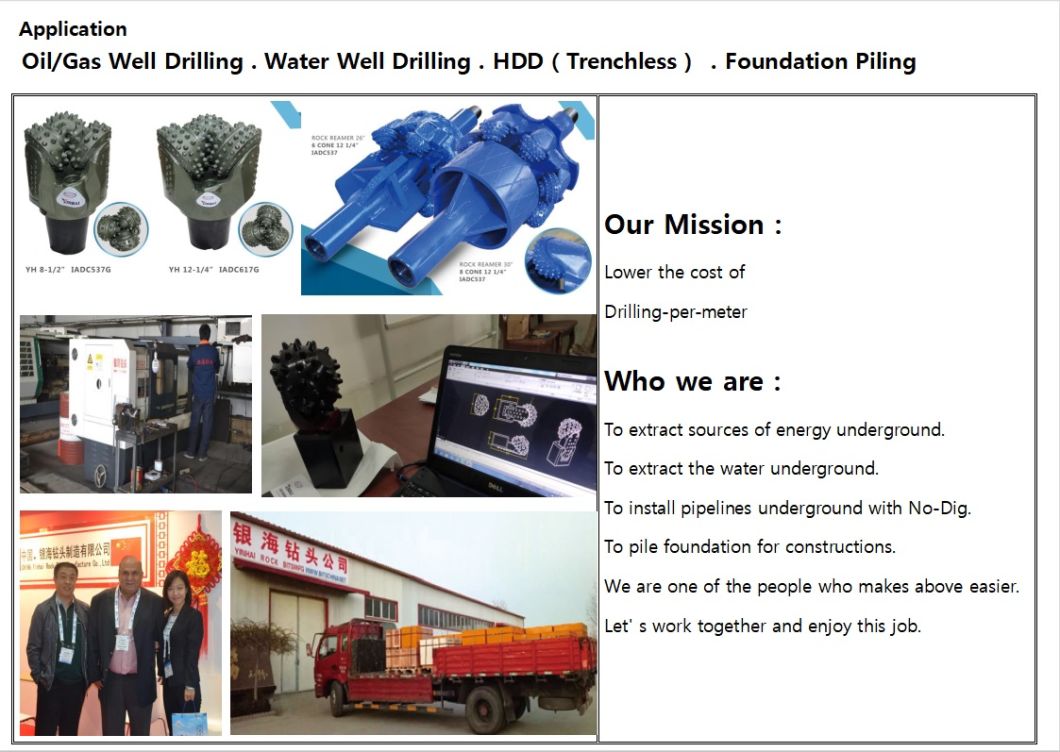

Basic Info.

HS Code

8207199000

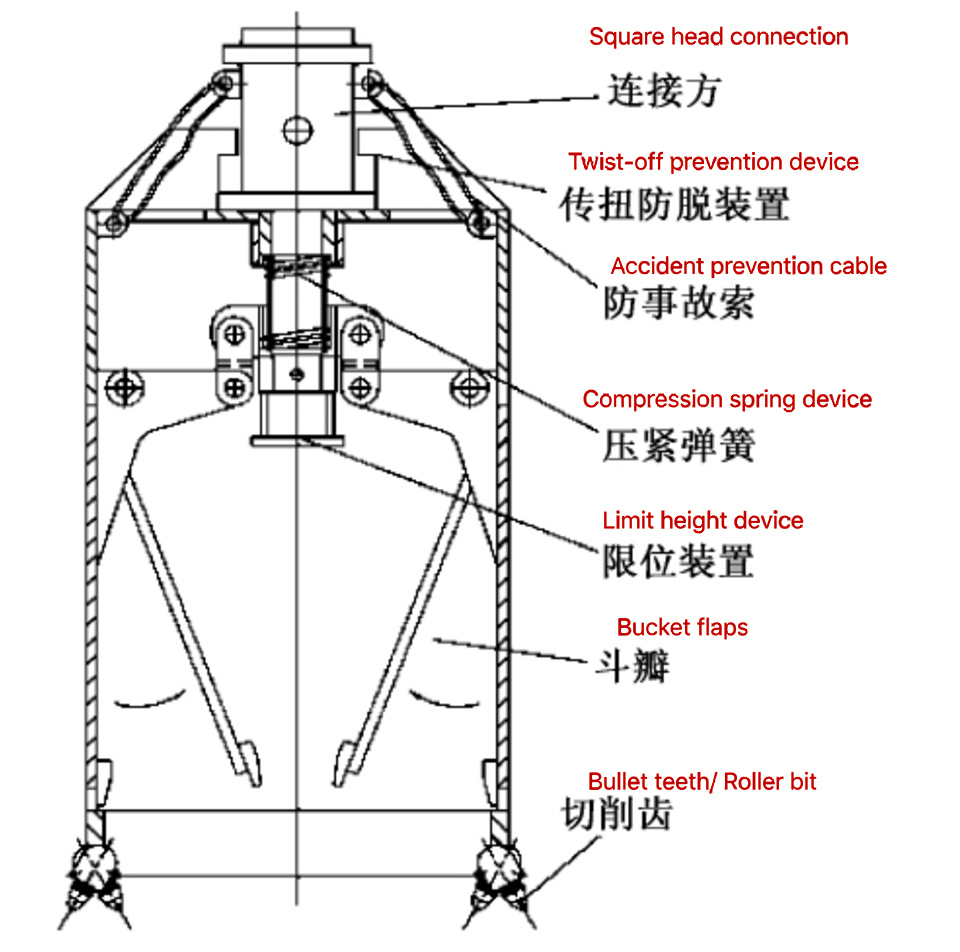

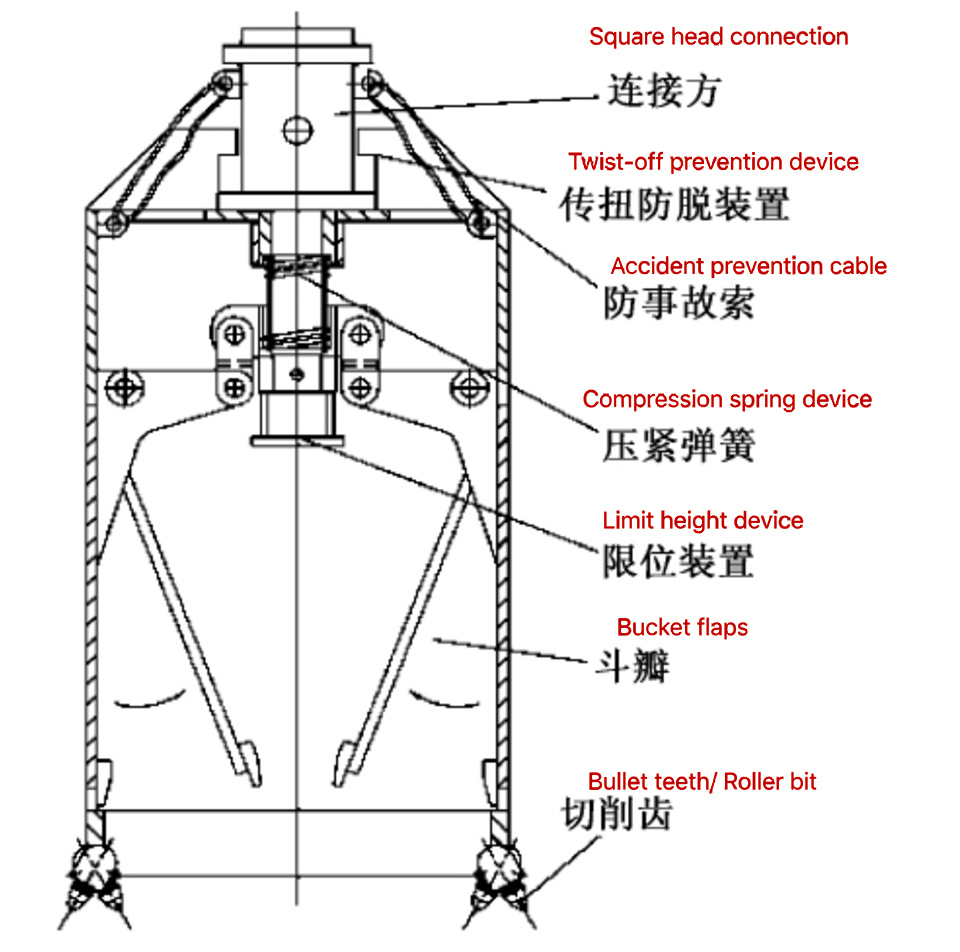

TECH DATA OF YINHAI Rock Bucket

Drill Operating Procedures of YINHAI Core Barrel

Drill Operating Procedures of YINHAI Core Barrel

The Advantages of YINHAI Core Barrel Roller Cone Bits

- The reamer bit consists mainly of four or more cones. The main cutting tooth are new wear-resistant alloys of tungsten carbide inserts . The new design and the new process of high quality tungsten carbide teeth improve the service life of the reamer drilling. The guiding is a roller core bit or a scraper drill bit.

- The bearing sealed uses high-performance O-ring sealing or metal sealing bearing and special greasing.

- Special carbide inserts are placed on the outer diameter of the head to reduce the wear of the head during the formation of abrasives in directional and horizontal wells, to prolong the life of the drill.

- The cost to replace a roller cutters is a fraction of the cost compared with replace a large tricone rock bit.

Drill Operating Procedures of YINHAI Core Barrel

Drill Operating Procedures of YINHAI Core Barrel - Before running the core barrel, the flexibilities of the mechanism must be checked at the orifice.

- Bucket flaps should enter the hole when fully stretched.

- The initial drilling can not be pressurized, then gradually pressurized after the backdrilling is stable. At this time, the core barrel should not appear to skipped(move up and down).

- If countersinking or stuck drilling occurs during drilling, stop pressurizing and do not use reversed drilling.

- During the drilling work, it was found that the slewing resistance suddenly increased. At this time, it can be preliminarily judged that the core has been broken, and it can be reversed 2 to 3 times, and the core barrel could be lifted.

- During the drilling process, sudden pressure loss is found, that there is no resistance when turning. need to stop drilling immediately and check to prevent the rotating shaft from breaking.

FAQ:

1.Q:What kind of packing ways do you have? A: Plywood case free of fumigation;wooden box ,steel box,carton box;packing can be customized. 2.Q:What is your advantages? A:We are 100% factory directly sales,API production process guarantee,Provide customized services for brand processing and OEM services.. Reduce the cost of drilling for you and give enough margin room for trading company, worry free after-sales service.Welcome to make video call to inspect factory. we have already build an outstanding technological innovative R&D department for guiding and technical support for after sales, also could offer the drilling feedbacks for your reference. 3.Q: How about the delivery and payment terms? Payment: T/T, L/C, Western Union, Paypal, 30% deposit in advance and rest before delivery. Min. order quantity: 1 piece. Transportation: By DHL/TNT/Fedex express, air, sea, train.